Knowledge

-

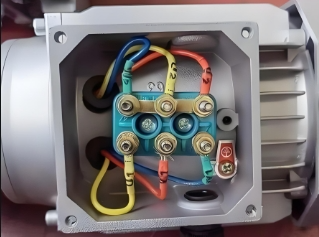

The benefits of keeping 6 terminals for three-phase motors

During an analysis and discussion on the connection method of three-phase motor windings, a netizen raised a question about the number of winding output terminals. For most three-phase motor windings, we can use different connection methods according to the line voltage, namely delta connection a...Read more -

Air gap size of asynchronous motor stator and rotor

The stator-rotor air gap is a necessary parameter for motor products, and different series of products have different requirements for air gap. The air gap of asynchronous motors is relatively small, and the size of the air gap has a greater impact on the no-load current of the motor. In order to...Read more -

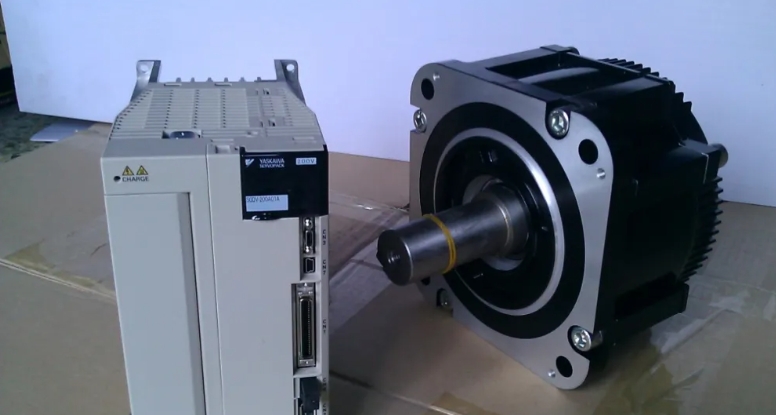

What problems are often encountered when using a frequency converter to power a motor?

A frequency converter is a device that converts industrial frequency power into other frequency power. The power frequency in our country is 50Hz. In the field of motors, in order to change the speed of the motor or other performance changes, many motors are powered by frequency converters. The f...Read more -

Analysis of the advantages and disadvantages of using closed slots in cast aluminum rotors of motors

As people continue to pursue motor efficiency, closed slot rotors are gradually recognized by motor manufacturers. For three-phase asynchronous motors, due to the existence of stator and rotor slots, pulsation loss will occur during rotation. If the rotor uses closed slots, the effective air gap ...Read more -

Fault Cases – Causes and Effects of Motor Noise and Winding Heating

Noise is a very typical failure case of motors. It can be divided into mechanical, electrical and ventilation types based on the mechanism of its generation. In comparison, the sound caused by electricity is easy to identify, that is, it can be judged by cutting off the power supply; and the nois...Read more -

Evaluate the energy-saving effect of YE4 and YE5 motors through power consumption

For any motor consumer, the motor’s power usage is a critical factor while the motor product meets its purpose. For electric motor products, rated voltage, rated power, efficiency, speed and current are all important performance indicators, while for power consumption, power and efficiency ...Read more -

Peanut picking machine structure and working principle

1. The structure of peanut picking machine The peanut picking machine is like a precise mechanical body, consisting of a frame, a transmission system, a picking mechanism, a lifting mechanism and a control system. 1. Frame: As the skeleton of the peanut picker, it supports and fixes other p...Read more -

New energy tractor market has broad development space

With the continuous innovation and development of the new energy technology revolution, the manufacturing and application technology of new energy agricultural machinery has gradually matured. In recent years, many domestic agricultural machinery companies have launched new energy tractors with d...Read more -

What are the obvious differences in structure between high and low voltage motors?

The fundamental difference between high and low voltage motors lies in the difference in rated voltage of the motors. It is precisely because of the difference in rated voltage that the motor components and materials are quite different. The difference in electromagnetic wires. Due to the large d...Read more -

Will the motor winding burn out in the no-load state?

A netizen asked why the winding of the shaded-pole motor would burn out when it is running at no load? To answer this question, we analyze the reasons why the winding of the motor is burned out when it is running at no load. Compared with the load, the no-load state of the motor is an operating s...Read more -

What influence does the transmission pulley have on the performance of the motor?

Transmission is a key link in the energy conversion of motor products. Common transmission methods include gear transmission, coupling transmission and belt transmission. When coupling transmission is used, the towed equipment and the motor have the same rotation speed, that is, the angular veloc...Read more -

Are high voltage motors more prone to vibration problems than low voltage motors?

Compared with low-voltage motors, high-voltage motors, especially high-voltage asynchronous motors, are mostly based on cage-type rotor structures. During the manufacturing and operation of the motors, due to improper matching of mechanical structural parts, the motors may cause severe vibrations...Read more